1.The composite frame pre-tightened with steel-wire of high fatigue property and bearing stability.

2.The new belt charging technology can make charging more even and realize the whole body pattern texture.

3.Mature die formation pressing process is adopted to make tile more compactand of higher quality. There is no need to cut edge before firing to reduce powder waste.

4.The deep back pattern can be set on the back of the tile by die formation, which is conducive to paving. And the mold has long service life and low cost.

5.The square cylinder have been patented and it has features of more even pressing load distribution, small brick deformation and fast pressing speed.

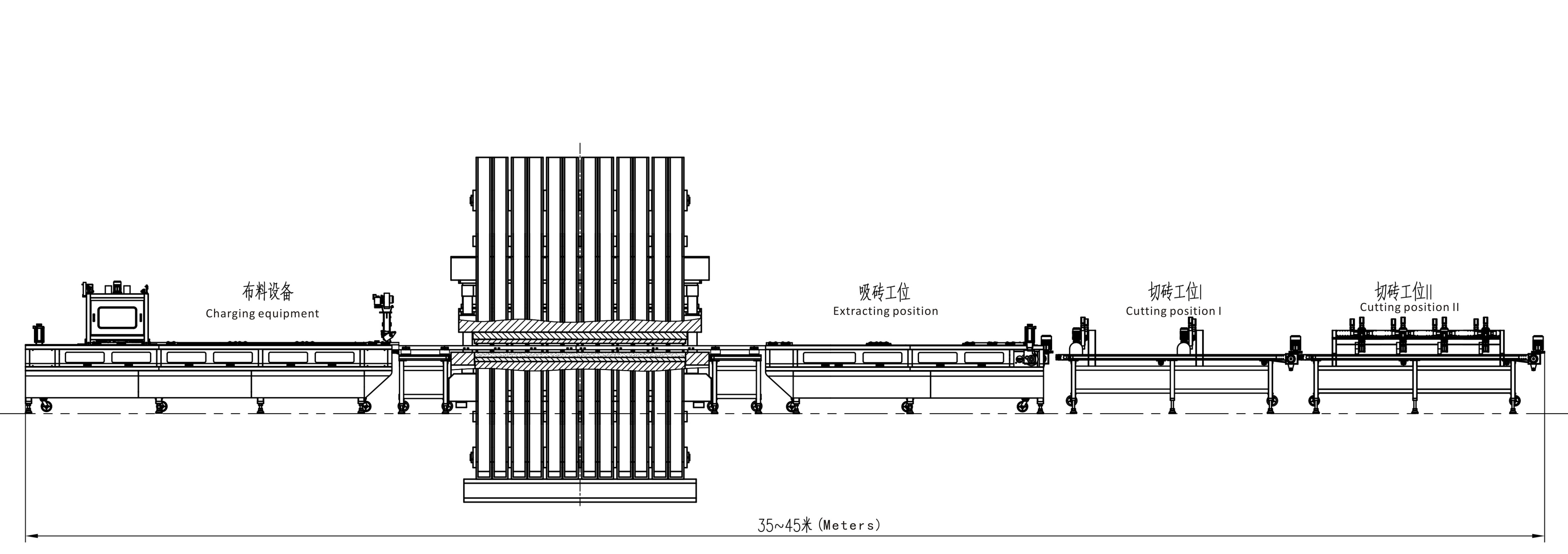

6.The tile width can be adjusted by replacing the mold and the tile can be cut into various specifications as required to realize flexible production.

7.It is equipped with quick die change system with short changing time and low labor intensity.

8.The equipments of the whole production system are all used by intelligent centralized control and management with the function of data network, which can be connected with MES, ERP and other factory production management systems.